THE PLANT

Fundiciones Carg has facilities with a total area of 5,275 m2 based on a plant of 4,000 m2 totally dedicated to the complete process of manufacturing of cores and moulding, melting, casting, shot blasting, deburring and painting.

- Foundry: 3.025 m2

- Finishing shop and warehouse: 1.500 m2

- Offices: 300 m2

- Patterns warehouse: 350 m2

- Maintenance workshop: 100 m2

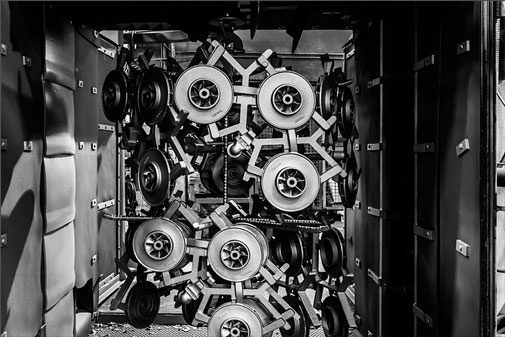

MOULDING

At Fundiciones Carg we have several automated and manual moulding lines that meet the following characteristics:

Automated moulding:

- Green sand automated moulding line, with boxes of 900 x 600 x300 / 300 mm destined to medium and small series for parts from 1 to 100 kg

- Semi-automated moulding line, with boxes of 1000 x 800 x 350/350 mm, dedicated to small series for parts from 10 to 200 kg

Manual moulding:

- Manual moulding line with boxes up to 2000 x 2000 mm, reserved for prototypes and special series of parts up to 2,000 kg

CORE Production

Fundiciones Carg carries out its own production of cores in its facilities. The manufacturing of the cores is done both in series and manually to supply our different moulding lines.

To carry out the production of cores, Fundiciones Carg has the following technology:

- Core shooting machine 16 l by Arabamendi

- Core shooting machine de 25 l by Foundry

- Core shooting machine de 34 l by Loramendi

- Core shooting machine de 40 l by Euromac

FUSION

Fundiciones Carg is committed to induction furnaces to carry out the fusion due to their greater energy efficiency and the high degree of temperature control they allow.

Fundiciones Carg trusts Inductotherm technology:

- Electric induction furnace of 6 Tn. (Mid-frequency)

- Electric induction furnace of 2 Tn. (Mid-frequency)

Blasting

At Fundiciones Carg we have blasting machines that provide a unique finish to our parts, treating the surface of the metal in such a way that it is strengthened, cleaned and polished optimally.

To carry out this process, we have the following machinery:

- Suspended load cabin of 1800 x 1800 mm Alju

- Rotating drum shot blasting machine Mebusa

DEBURRING

In Fundiciones Carg we have a complete deburring workshop to provide each of our parts with the perfect finish.

Fundiciones Carg cuenta con:

- 8 cabins for manual deburring

- 1 Vulcan machine for automatic deburring

- 2 machines for automatic deburring

FINISHING

Fundiciones Carg offers an integral service to its clients. The parts manufactured in our company are delivered with a perfect finish according to the requirements of each client. For this, we have a painting workshop that gives the parts the best of finishes.

INSPECTION

Fundiciones Carg watches over quality throughout the production process, thus guaranteeing the optimum character of each of our parts. The technical team of FC works with the most avant-garde technology to carry out the quality control in each phase of the manufacturing obtaining the best results.